Clothing manufacturers play an essential role in helping fashion designers get their lines out to the public. From the initial preproduction stage to the final quality control inspections, fashion designers rely on the skills the manufacturer brings to the table. However, there is a price to pay for the manufacturing process. The fashion designer will have to pay not only for the manufacturer’s skills and time, but also for the materials used to bring their lines to life. If the designer wants their completed line shipped to them, there will also be costs associated with that as well. So, how much does it cost on average to manufacture a clothing line from start to finish? Let’s find out…

The average cost to produce clothing in the United States is $25 per piece, while it costs $15 per piece on average in China. There are a few factors that determine how much it costs to manufacture clothing, including the complexity of the design; the type of material used; any embellishments made to the design, and packaging and logistics.

Let’s read along to see seeing how the manufacturing process is affected by the many decisions made by the designer throughout production. We will take the look at how using various materials and cuts of fabric can play a major role in the cost of manufacturing clothing. In addition to material, we will also learn how embellishments made to garments can affect production costs, and how packaging and logistics also play a part in how the manufacturer determines what they charge to make a clothing line.

Complexity of the Design

When determining how much it will cost to manufacture clothing, one of the most important things that factors into the price is how complex the design is. If the design is simple, it will cost significantly less to produce than an elaborate or intricate design. For example, a simple, basic sun dress will not be nearly as expensive to manufacture as an evening gown or a prom dress. While we may all accept this as common knowledge, some of us may not know why this is the case. The answer is that the manufacturer’s job becomes much easier if the piece in question has a simpler design. From cutting to sewing, each step of producing a clothing line becomes much easier when the designer keeps the it simple.

Fortunately, simple designs are considered a bona-fide classic when it comes to fashion, but there are more benefits to these designs than just being fashionable. Simple pieces usually have clean, straight lines and the material is usually much easier to cut and sew than complex pieces, which means that the manufacturer will have to put less effort into producing it. They can then pass the savings along to the designer, who can sell the merchandise to their customers for a fair price as well. Choosing a basic design that was easier to manufacture can possibly lead to a higher sales volume, which can result in higher revenue and profits. That makes everybody involved much happier.

Advantages and Disadvantages of Opening A Clothing Boutique.

Type of Material

If there is one characteristic of a design that is just as important as its complexity in manufacturing, it is the type of material that the designer chooses for the piece. We are all aware that cashmere costs quite a bit more than cotton, buy why is that? According to Sewing Is Cool, wholesale materials are priced by the category and the quality of the material being sold. Fabrics are also priced by how fine they are and by their weight, with finer and heavier fabrics being more expensive than those of lesser quality. However, fabrics with finer texture and are less dense may also be priced higher than heavier materials that are more coarse. For example, silk will be much more expensive than polyester, even if it is significantly lighter. This is because silk is a material that is found naturally and harder to obtain than a material that can be easily made.

Just in case you were wondering what the most expensive material is that can be used to produce clothing, I have the answer for you. Per the website A Luxury Travel Blog, the wool from the vicuña takes the cake at a whopping $3,400 per yard! Now, I know that the majority of you are probably wondering why this type of wool is costs so much. It’s because the wool of the vicuña can only be taken from the animal once every two or three years, which makes it one of the hardest naturally occurring materials to get in large quantities. Two other members of the camelid family whose wool is also quite expensive are the alpaca and llama. Another reason for the wool of these creatures being so costly is that they are feral, which means that they are not easily caught in the wild. Three other factors that drive up the price of the wool from these camelid is that it is known for being exceptionally warm, soft, and luxurious.

Embellishments Made

The third factor that can drive up the cost of manufacturing clothing is the embellishments that have to be made to the product. If you are anything like me, you are probably wondering what embellishments are. Thankfully, the good people at So Sew Easy have clarified this for us. They define embellishments on garments as extra features that make the piece attractive to the customer. Some of the most popular embellishments include rhinestones, embroidery, bows, and printing. While most embellishments don’t have a practical use, they typically add value to the piece, which means that it can be sold for more money, increasing overall profits for the clothing line.

The largest cost of manufacturing clothing comes from the fabrication process, which is a astonishing 60%, per Lefty Production Co. Product embellishments play a key role in this because of the additional attention, skill, and time that must be devoted to the clothing line. Believe it or not, these small additions to the garment are important to the designer, even though they may seem fairly insignificant to the majority of us. However, while most consumers may not see these embellishments as an important addition to the overall value of the garment, they are still a huge selling point and a major part of the artistic design. They give the garment an appeal that an article of clothing with the same basic design simply won’t have. They make that one piece stand out amongst a plethora of similar pieces.

Five Reasons You Should Start A Fashion Business

Packaging, Shipping and Logistics

Although this may be the final stage of the manufacturing process, it also plays a part in determining how much the manufacturer will charge to produce a clothing line. Some clothing does not require special storage requirements or packaging. However, the more expensive clothing made from premium materials may have exact storage and packaging specifications that must be adhered to in order to prevent the final product from being damaged or ruined before it can make it to retail shops to be sold. I’m sure that it goes without saying that these items are going to cost quite a bit more to meet these special requirements, which will be also be reflected in the manufacturing cost of producing the clothing. In addition, the line’s designer may ask for special packaging for their clothing, even if the type of material doesn’t require it.

Shipping is another element of manufacturing that are often overlooked as parts of production that can add to the overall cost. Of course, the larger the run is, the more likely it may be that the manufacturer offers the designer a reduced rate to ship the final product. Repeat customers may also be offered a discount on various facets of manufacturing. Still, the manufacturer will be at the mercy of the rates of their shipping service. However, shipping is only once part of logistics, which is defined as “the overall process of managing how resources are acquired, stored, and transported to their final destination,” per Investopedia. The origins of the term came from the way that the military used to obtain, store, and move equipment. There are many people who have to work in unison to get the clothing to its final destination, and all of them have to get paid.

Conclusion

There are many different things that go into the $25 average price per piece that it will cost to have clothing manufactured in the United States. Perhaps the two most influential elements are how much the manufacturing process will cost are the complexity of the piece’s design and the material from which the garment is made. Simpler pieces made from less luxurious materials will cost much less to produce than complex garments made from finer materials. The most expensive fabrics for making clothing are usually naturally occurring materials that are much harder to secure than less expensive manufactured fabrics.

Embellishments add to the athletic appeal of the piece, which makes them more profitable for the designer. They are also fairly difficult to include during manufacturing, which is why the manufacturer will charge the creator more to produce pieces that have them. A few other elements that add to the overall cost of production include packaging and logistics, which is a blanket term for all of individual processes it takes to get the finished clothing to the client. It takes a lot of people working plenty of hours to make this step happen, and it can definitely add to the total cost of manufacturing. If you are a designer in the market for a manufacturer, be sure to inquire about these costs to get a clearer idea of how much you can expect to pay to see your pieces come to life.

How Much Can You Make As A Design Major?

Related Questions

What are the top clothing manufacturers in the United States?

There are certainly no lack of clothing manufacturers in the United States. In fact, there are well over 100,000 textile mills found in the United States alone. However, if you are searching for the top clothing manufacturers in America, they are as follows:

- American Stitchco, Inc.

- Carolina Glove Co.

- AdCapitol

- Synergy Dyeing and Finishing Co.

- Crumpton Welding Supply & Equipment, Inc.

What steps to are included in the manufacturing process of clothing?

Although some manufacturers may have some steps in the manufacturing process that differ from others, they all follow the same basic steps to produce clothing. These steps include:

- Pre-Production

- Fabric and Trim Sourcing

- Pattern Making

- Production Planning

- Cutting Process

- Manufacturing and Quality Control

- Delivery

To learn more about how to start your own fashion clothing line check out my startup documents here

Please note: This blog post is for educational purposes only and does not constitute legal advice. Please consult a legal expert to address your specific needs.

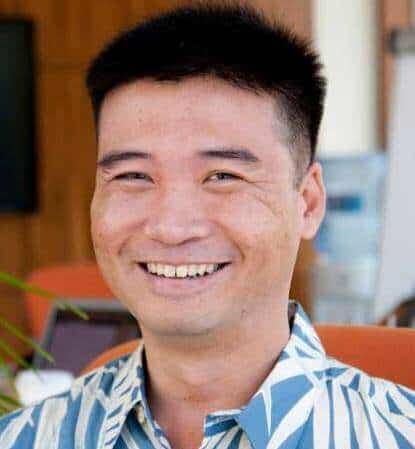

Meet Shawn Chun: Entrepreneur and Fashion Business Fan.

I’m a happy individual who happens to be an entrepreneur. I have owned several types of businesses in my life from a coffee shop to an import and export business to an online review business plus a few more and now I create online resources for those interested in starting new ventures. It’s demanding work but I love it. I do it for those passionate about their business and their goals. That’s why when I meet a designer or boutique owner at a craft fair, farmers market, retail location or anywhere else I see myself. I know how hard the struggle is to retain clients, find good employees and keep the business growing all while trying to stay competitive.

That’s why I created Fashion Business Boss: I want to help fashion business owners like you build a thriving business that brings you endless joy and supports your ideal lifestyle.